Model 175

Belt conveyor oven for heat-shrinkable tubing, thermal processing and curing.

Model 175R

Belt conveyor oven for heat-shrinkable tubing, thermal processing and curing with a reversing drive circuitry to prevent the loading of parts if temperature is out of range.

Model 425

Discrete part shuttle oven for heat shrinkable tubing, thermal processing and curing.

One piece construction with small area footprint.

Concave ceramic heating elements for efficient focused heating of components.

Normal operating temperature of 0-600′.

The dwell period is digitally set by a timer in one second increments with a range of 1 to 9999 seconds.

Model 105

Tunnel Oven for heat-shrinkable tubing, thermal processing and curing.

One meter standard conveyor length. This can be extended to up to 200″ on custom orders.

Wire mesh belt conveyor

Two height positions for the upper element assembly ( 2.11” and 3.86”)

Normal operating temperature of 0-600′.

Two 8” x 15.25” opposing 1500 Watt infrared elements.

Temperature set-point and conveyor speed can be controlled to accommodate a wide variety of products.

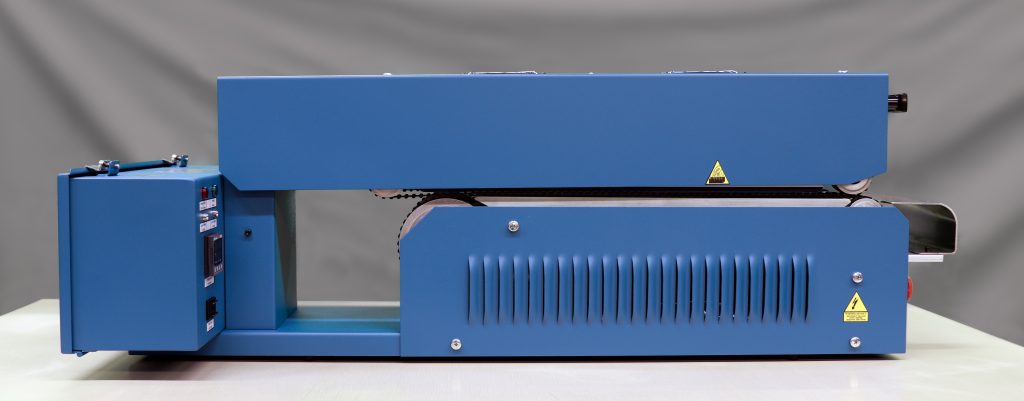

Model 185

Belt Conveyor Oven for heat-shrinkable tubing, thermal processing and curing.

The Model 185 Belt Conveyor Oven is an enhanced version of our Model 175, suitable for heating a variety of products, including heat-shrinkable tubing, solder paste applications, and thermal curing of various products.

Available in two width configurations. The “S” configuration is offered with 3.75” wide heating elements for splices up to 4” long. The “W” configuration is offered with 6.00” wide heating elements for splices up to 6.50” long.

Normal operating temperature of 0-600’C.

Temperature set-point and drive speed can be controlled to accommodate a wide variety of products.

Lock out gate to prevent the loading of parts if temperature is out of range.