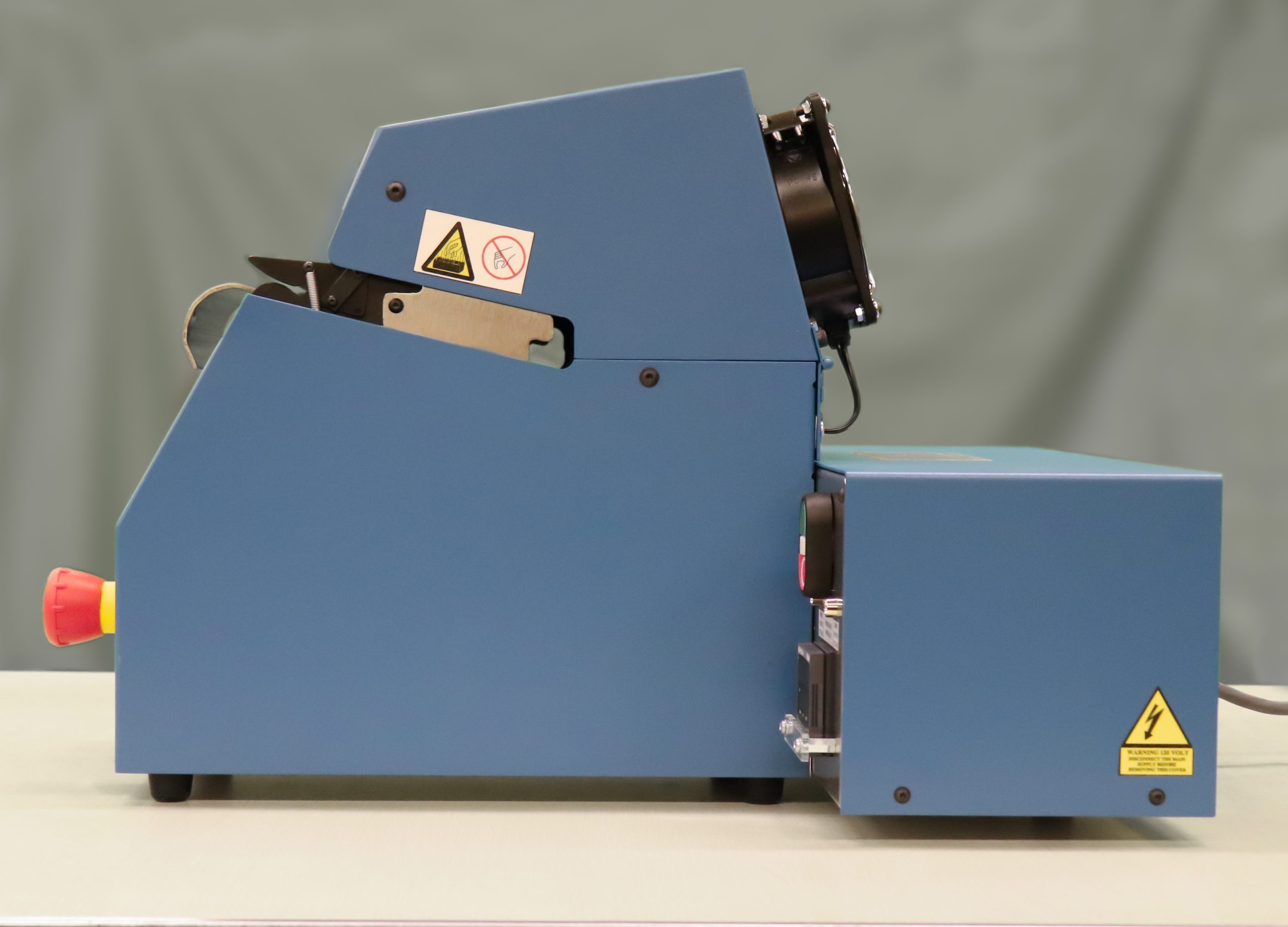

Model 425

$7,300.00

Discrete part shuttle oven for heat shrinkable tubing, thermal processing and curing.

- One piece construction with small area footprint.

- Integrated control panel with rear mounted electrical and pneumatic power connections.

- “0” Voltage detect circuitry to prevent machine restart after a power outage.

- Concave ceramic heating elements for efficient focused heating of components.

- Wide carriage guiding system for stable shuttle motion.

- Sinusoidal opener cams for smooth shuttle motion.

- Control circuitry to prevent cycling when process temperature is out of range.

- Auxiliary port connection for optional foot switch.

- 20 Minute solid state cool-down timer to eliminate thermal sensor failures.

- Temperature out of range indicator light.

- E-Stop circuitry for immediate shut-down in a critical condition.

- Quarter-Turn fasteners for easy removal of lower sheet metal cover.

- CE compliant electrical components.

Description

The Model 425 Discrete Part Shuttle Oven is a low maintenance, electro pneumatic thermal processor suitable for heating a variety of products, including heat-shrinkable tubing, solder paste applications, and thermal curing of various products.

The unit is designed for cyclical processing of products. High volume thermal processing on the M425 is achieved by sequentially stepped manufacturing methods designed to maximize production put through.

The M425 is designed as an integrated unit consisting of processor shuttle drive, heating chamber, and attached control enclosure.

Assemblies are positioned on the entry alignment tray using centering markers, and inserted into left and right side gripping jaws. When the cycle start is initiated the pneumatic cylinder retracts the assembly into the heating chamber for a selectable dwell time period, the completed assembly is then returned to the load position.

The pneumatic drive system incorporates sinusoidal cams to open the oven chamber during the cylinder retraction and extension of the assembly, creating smooth vibration free travel.

The drive cylinder incorporates a custom designed wide carriage shuttle slide. The wide carriage system creates a minimum of side to side rotational motion during cycling of the unit.

The M425 oven chamber has two 500 watt ceramic infrared heating elements, above and below the product entry pass line. The heating chamber oven is insulated with thermal reflectors and molded high temperature insulation.

The temperature of the heating elements is precisely maintained by a closed loop temperature controller.

The M425 is equipped with an amber indicator light to advise the operator of the status of the unit. The amber light when illuminated indicates temperature out of set-point range. When the light turns off the temperature is within band and the processor is ready for operation. The processor will not cycle when the out of range indicator light is illuminated.

The M425 processor is available in either 115VAC or 230 VAC, single phase, 50/60 Hz.

The M425 is designed to meet the requirements of the Occupational Safety and Health Administration (OSHA), the National Electrical Code (NEC) and European Compliance requirements.

Sheet metal guards and fans protect the operator from exposure to the temperature in the heating chamber. The processor has an automatic cooldown circuit to prevent heat damage to the components when the unit is powered off.

Controlled heating zone. The Model 425 Processor uses opposing 500 watt ceramic heating. Consistent oven chamber temperature is obtained through a K-type thermocouple embedded into the upper heating element, and a closed loop PID temperature controller. Two LED lights provide the operator with visual indicators of the upper and lower heaters cycling. When the element temperature is not within the process temperature control range, a temperature “Out of Range” indicator light illuminates.

Shuttle speed control and Dwell time. The shuttle velocity is set by integral speed controls mounted in the solenoid air valve. The dwell period that the assembly remains in the heating chamber is digitally set by a timer in one second increments with a range of 1 to 9999 seconds.

Minimal skill requirements. There are centering guides for aligning the assembly as well as the tubing device being processed. The operator only needs to center the assembly and the tubing or device and depress the cycle start button. The air cylinder driven grippers carry the assembly into the heating oven for a predetermined time and return the assembly to the operator load position.

Versatility. The processor is designed to process a broad range of heat-shrinkable products up to ¾ inch in diameter and 4 inches in length. The infrared energy source is ideally suited to

efficient processing of either single wall or dual wall adhesive-lined tubing. Temperature set-point and dwell time can be controlled to accommodate a wide variety of products and substrates.

Safety features.

• Circuit breaker for current overload and mains power disconnect.

• Emergency Stop push-button for immediate shut down of the unit in a critical situation.

• Automatic cool-down circuit to prevent heat damage to integral components.

• Over temperature thermal switch to shut the unit down if an over temp condition is sensed.

• Indicator lights to advise operator of proper heater cycling and heater failure.

Options.

• Remote start port for foot switch or anti-tie-down cycling.